YH408

- Categories : YH series

• The injection part adopts a linear guide rail structure, which is stable,efficient and energy-saving.• It can meet the requirements of high-precision product molding,improve the injection speed and response, significantly improve themolding quality and precision.• The latest "excellent" integrated computer is used to comprehensivelyimprove the positioning accuracy and improve the overall operationstability.

Technical parameter

YH Series Servo Energy-Saving Injection Molding Machines | ||||||

YH-408 | ||||||

International Size Rating | 2650 | |||||

Injection Unit | ||||||

Screw specification | A | B | C | D | ||

Screw diameter | mm | 70 | 75 | 80 | / | |

Screw ratio | L/D | 21.4 | 20 | 18.8 | / | |

Theoretical injection capacity | cm³ | 1327 | 1524 | 1734 | / | |

Injection weight | g | 1208 | 1387 | 1578 | / | |

Injection rate | g/s | 366 | 395 | 446 | / | |

Injection pressure | Mpa | 199 | 173 | 152 | / | |

Screw rotation speed | r/min | 0-160 | ||||

Clamping Unit | Auxiliary machine specifications | |||||

Clamping force | KN | 4080 | Dryer | 150kg | ||

Mold opening stroke | mm | 710 | Feeder | 800g | ||

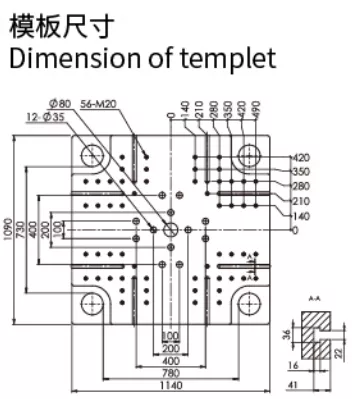

Space between tie bars | mm | 760×670 | Air switch specification | 160A | ||

Max.Mold Height | mm | 780 | Power cord specification | 35mm² | ||

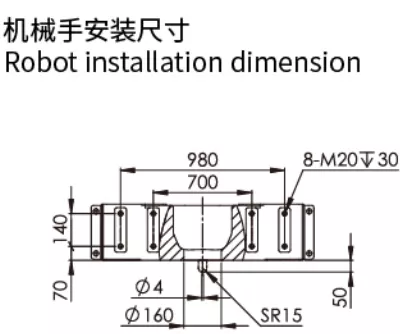

Min.Mold Height | mm | 250 | Mold positioning ring specification (mm) | Ø160 | ||

Ejector Stroke | mm | 200 | Nozzle aperture (mm) | Ø4 | ||

Ejector Force | KN | 110 | Nozzle spherical R angle | SR15 | ||

Others | Mold clamping screw specification | M20 | ||||

Oil pump motor power | KW | 43.2 | Template outline dimension (mm) | 1070×1120 | ||

Heater power | KW | 27.6 | Foundation bearing requirement | 3t/m² | ||

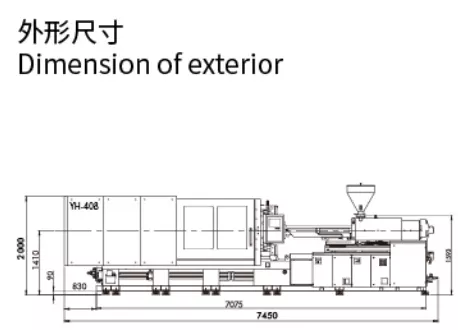

Machine dimension | M | 7.45×2×2.45 | Oil cooler water flow requirement (L/min) | 118 | ||

Machine weight | T | 16 | Cooler inlet and outlet pipe interface | 1-1/4″ | ||

Hopper capacity | L | 50 | Minimum mold size (length × width) (mm) | 545×510 | ||

Oil Tank Capacity | L | 600 | ||||

Instructions: 1. Theoretical injection volume = cross-sectional area of the injection molding machine's barrel × injection stroke 2. Actual injection volume = theoretical injection volume × 0.91 (calculated based on GPPS) | ||||||

Product Description

Application Cases

• The injection part adopts a linear guide rail structure, which is stable,

efficient and energy-saving.

• It can meet the requirements of high-precision product molding,

improve the injection speed and response, significantly improve the

molding quality and precision.

• The latest "excellent" integrated computer is used to comprehensively

improve the positioning accuracy and improve the overall operation

stability.

Full system standard proportional back pressure valve

Roller Hopper Slide

The system pressure is raised to 17.5Мpa

Non-welding technology of main power pipe

New graphite self-lubricating steel sleeve

JSK standard appearance upgrade

Injection Unit

Double cylinder balanced injection structure

High efficiency plasticizing screw barrel of high quality nitride steel

Timing heating function,screw anti-cold start

High quality high torque hydraulic motor drive glue

Screw retraction anti-salivation device [glue extraction/loose retraction/fire retraction]

Double injection shift cylinder design ensures uniform nozzle contact force and injection control accuracy

The high rigid pedestal support structure ensures the stable ano efficient operation of the injection mechanism

Nozzle to center trimming device

High precision electronic ruler controls the shooting stroke

Six stages of injection,five stages of pressure,four stages of material storage pressure,speed can be adjusted

Screw speed measuring device

Automatic cleaning the barrel function

Centrally lubricated with station as standard

The injection seat/pre molded seat adopts a linear guide rail support structure

Standard nozzle protection cover

Clamping Unit

Five fulcrum oblique double toggle

Conjucted structure of clamping plate and end board

High precision low pressure protection die function

Hydraulic motor drives automatic gear die setting

reduces the bearing deformation of tie rod,and themovable form work moves high hardness steel belt

Adjustable movable form work supporting structure

Self-detector

volumetric centralized

lubrication

system

Standard mechanical and electrical double safety protection devices

The operation of opening and closing election are controlled by high-precision electronic ruler

Multiple ejection modes are available,with pressure and speed setting respectively

Five process in mold opening and closing adjustable pressure

Hydraulic Unit

Efficient servo energy-saving system

Increase the system pressure to 17.5Mpa

Non welding technology of main power pipe

Oil temperature detection, automatic alarm for oil temperature deviation

Mold cooling water drain [including a set of material

pipe cooling!

Full series standard proportional back pressure valve

Control Unit

High response injection molding machine special control computer

Intelligent SPC quality management

Support for multiple languages

LCD color screen, real-time animation display of machine operation

Simple robot electrical interface

Parameter data protection lock

PID temperature automatic control, to achieve the barrel temperature selt-correction

USB interface for easy panel program update and mold

parameter

backup

PROHIBIT TON

With stop memory function, can store 100 sets of mold data randomly

100 sets of exception alerts and 100 sets of change record stores

Muti-level password protection, can he set according to different authorization levels, to prevent error modification of molding parameters

Below 308T is equipped with blanking port detection electric sensor

Front and rear door emergency stop switch as standard

Spare aviation sockets [5-core are three-phase 380V]:below 268T:5-core 16Ax3 group,308T-408T:5-core 32Ax1 group+5-core

16Ax2 group

Get In Touch

Request A Quote