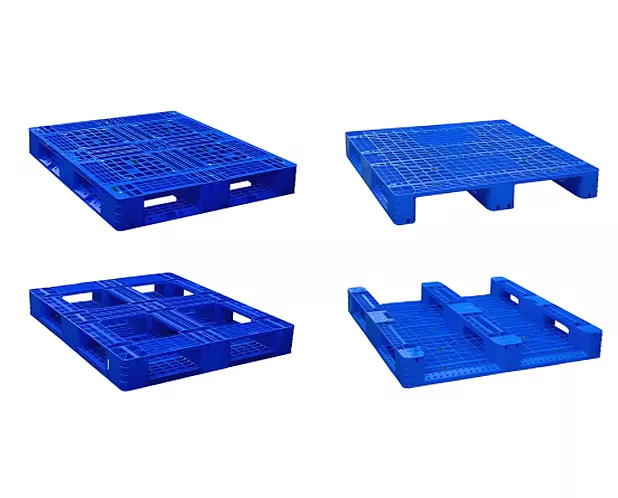

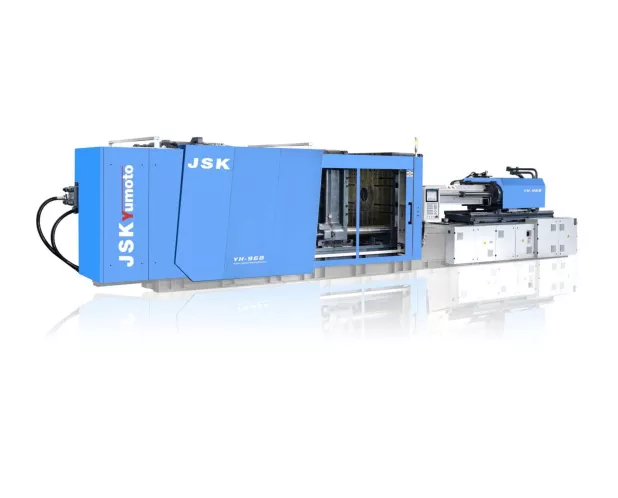

Large-Scale Plastic Pallet Dedicated Injection Molding Machine

- Categories : Special custom series

Introduction to Large-Scale Plastic Pallet Dedicated Injection Molding MachineWith the rapid development of the logistics and warehousing industries,the demand for plastic pallets is continuously increasing.Plastic pallets,known for their durability,lightweight,and recyclability,have become the idea

Technical parameter

YH Series Servo Energy-Saving Injection Molding Machines | ||||||

YH-968 | ||||||

International Size Rating | 7100 | |||||

Injection Unit | ||||||

Screw specification | A | B | C | D | ||

Screw diameter | mm | 90 | 100 | 110 | 120 | |

Screw ratio | L/D | 25 | 23 | 21 | 21 | |

Theoretical injection capacity | cm³ | 3117 | 3848 | 4657 | 5542 | |

Injection weight | g | 2836 | 3502 | 4238 | 5043 | |

Injection rate | g/s | 533 | 658 | 796 | 947 | |

Injection pressure | Mpa | 227 | 184 | 152 | 128 | |

Screw rotation speed | r/min | 0-111 | ||||

Clamping Unit | Auxiliary machine specifications | |||||

Clamping force | KN | 9680 | Dryer | kg | ||

Mold opening stroke | mm | 1130 | Feeder | g | ||

Space between tie bars | mm | 1130×1080 | Air switch specification | A | ||

Max.Mold Height | mm | 1100 | Power cord specification | mm² | ||

Min.Mold Height | mm | 450 | Mold positioning ring specification (mm) | Ø | ||

Ejector Stroke | mm | 320 | Nozzle aperture (mm) | Ø | ||

Ejector Force | KN | 215 | Nozzle spherical R angle | SR | ||

Others | Mold clamping screw specification | M | ||||

Oil pump motor power | KW | 38.8+38.8 | Template outline dimension (mm) | |||

Heater power | KW | 56.6 | Foundation bearing requirement | |||

Machine dimension | M | 11.2×2.7×2.5 | Oil cooler water flow requirement (L/min) | |||

Machine weight | T | 48 | Cooler inlet and outlet pipe interface | |||

Hopper capacity | L | 100 | Minimum mold size (length × width) (mm) | |||

Oil Tank Capacity | L | 1610 | ||||

Instructions: 1. Theoretical injection volume = cross-sectional area of the injection molding machine's barrel × injection stroke 2. Actual injection volume = theoretical injection volume × 0.91 (calculated based on GPPS) | ||||||

Product Description

Introduction to Large-Scale Plastic Pallet Dedicated Injection Molding Machine

With the rapid development of the logistics and warehousing industries,the demand for plastic pallets is continuously increasing.Plastic pallets,known for their durability,lightweight,and recyclability,have become the ideal choice for modern logistics transportation and storage.To meet this market demand,we have specifically launched a large-scale plastic pallet dedicated injection molding machine.Here are the main features of this machine:

Designed Specifically for Pallets

• Large Mold Compatibility:The machine is designed to accommodate the large size of plastic pallets and can adapt to molds of various specifications,meeting diverse production needs.

• Optimized Injection System:Tailored for the thick-walled structure of plastic pallets,the injection system is optimized to ensure uniform filling of the mold with plastic,resulting in high-quality pallet products.

High Stability

• Robust Machine Structure:Made with high-strength steel and advanced welding techniques,the machine's structure is robust and stable,reducing vibration during operation and extending the equipment's service life.

• High-Precision Linear Guides:Equipped with high-precision linear guides to ensure smooth and precise mold opening and closing,enhancing production efficiency and product quality.

• T-Slot Template Design:The T-slot template facilitates quick mold installation and adjustment while enhancing the template's strength and stability,ensuring efficient and reliable production processes.

Energy-Efficient and High-Performance

• Advanced Energy-Saving Technology:The machine uses an energy-efficient drive system that significantly reduces energy consumption compared to traditional injection molding machines,lowering electricity costs.

• Smart Energy Management System:Automatically adjusts power according to production needs,further optimizing energy utilization efficiency and reducing operating costs.

• Fast Molding Cycle:Optimized injection and cooling systems ensure a fast molding cycle,improving production efficiency to meet large-scale production demands.

Precise Control

• High-Precision Control System:Equipped with an advanced control system that accurately controls key parameters such as injection pressure,speed,and temperature,ensuring the stability and consistency of plastic pallet quality.

• User-Friendly Interface:An easy-to-use interface allows operators to conveniently monitor and adjust production parameters,ensuring efficient and stable production processes.

Efficient Production

• Synchronized Mold Opening and Material Storage:The machine can store material while opening the mold,significantly reducing the production cycle and enhancing production efficiency.

• Quick Mold Change System:Supports rapid mold change,minimizing machine downtime and further improving production efficiency.

The large-scale plastic pallet dedicated injection molding machine,with its specialized design for pallets,high stability,energy efficiency,and precise control,is an ideal choice in the plastic pallet production field.It can meet the demands of large-scale production while helping enterprises reduce production costs and enhance market competitiveness.

Application Cases

Get In Touch

Request A Quote