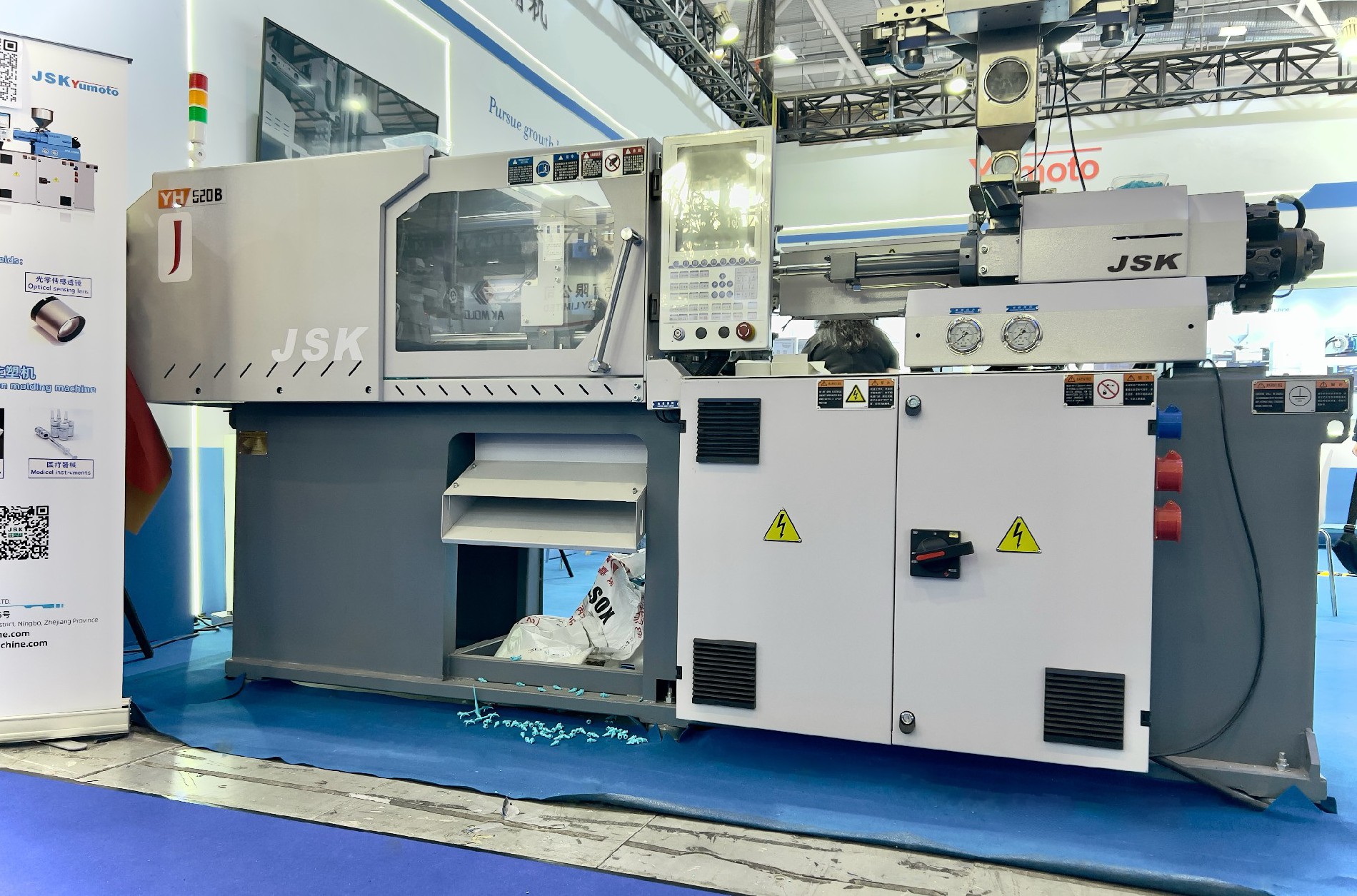

JSKyumoto High-precision Injection Molding Machine: Shaping Quality and Forging the Future

In the fierce competition of the injection molding machine market, various brands are vying with each other

to show their unique features. However, the JSK Yonghua High-precision Injection Molding Machine, relying

on its solid technology and reliable performance, has been working diligently and quietly, bringing practical

and high-quality injection molding solutions to industry customers.

Three Core Highlights to Unlock a New Injection Molding Experience

1. High-precision Control, True Quality Revealed in Details

The JSK Yonghua High-precision Injection Molding Machine is equipped with an advanced sensing and

control system, which enables precise regulation of parameters such as injection volume, pressure, and speed.

When manufacturing products with extremely high precision requirements, such as precision electronic

components and optical lenses, it can stably produce products with accurate dimensions and smooth surfaces,

effectively reducing the defective product rate and increasing the yield rate of products.

2. Energy-saving and Efficient, Facilitating Cost Reduction and Efficiency Improvement

The equipment is equipped with an intelligent energy-saving module that can automatically adjust the power

according to the production status, reducing energy consumption. The optimized hydraulic and heating-cooling

systems work in coordination. Compared with some similar products, the injection molding cycle is shortened.

While saving costs, it significantly improves production efficiency and creates greater value for enterprises.

3. Stable and Reliable, Ensuring the Entire Production Process

The machine body is made of high-strength materials, and key components are carefully selected from high

-quality brands in the industry. After multiple rounds of quality inspections and simulated working condition

tests, it can maintain stable operation even when facing long-term and high-intensity production tasks,

reducing the downtime caused by equipment failures and ensuring seamless production.

Diverse Application Scenarios, Adaptable to Different Needs

1. 3C Electronics Manufacturing: Mobile phone casings, precision structural components, electronic connectors...

It meets the requirements of lightness and miniaturization of 3C products, injecting high-quality genes into

electronic products.

2. Medical Equipment Production: It complies with the strict standards of the medical industry and is used for

manufacturing disposable syringes, medical device casings, etc., ensuring the safety and reliability of products.

3. Automobile Parts Processing: From automobile interiors to headlights and bumpers, it helps automobile

manufacturers achieve lightweight and integrated design of parts.

4. Optical Instrument Manufacturing: It precisely controls the curvature and thickness of lenses, ensuring

optical performance and meeting the high-precision requirements of optical instruments.

Review of the Shenzhen Exhibition: A Splendid Debut and Gained Attention

From April 15th to 18th, 2025, the JSK Yonghua High-precision Injection Molding Machine made a grand

appearance at the Shenzhen Exhibition! Through on-site practical demonstrations of the equipment and

the display of a large number of samples, it attracted many industry partners to stop and communicate.

Many customers expressed their recognition of the equipment's performance and actively inquired about

the details of cooperation.

In the future, JSK Yonghua will continue to uphold the spirit of innovation, optimize product performance

and services, and join hands with industry colleagues to inject new impetus into the development of the

injection molding field!